High Quality for Precision Grinding Machine - Gravure Grinding Wheel Polishing Wheel – DongYun

High Quality for Precision Grinding Machine - Gravure Grinding Wheel Polishing Wheel – DongYun Detail:

Grinding wheel Specifiction:

Grit: #60 #180 #320 #400 #600 #800 #1000 #2000 #2500 #3000 #6000 , Grit can be customized according to your requirements.

Size(ODxIDxThickness): 200x50x50mm, 200x50x70mm, 200x50x100mm,200x100x50mm

Shape : Round, Polygon

Description Of Grinding wheel

1) New, light weight ,environmentally friendly, non-toxic, odorless, harmless to human body;

2) The life time is 1.6 times as high as that of the ordinary grinding stone,Ra is up to 0.02um or even higher, which can significantly improve the surface roughness of workpiece to mirror effect.

3) High cutting force ,low stone wear ,lower price help the client to cut down the basic cost with good perfomance effcient.

4) Use resin sintering process, featuring great mechanical strength, stable quality, and long-lasting wear resistance.

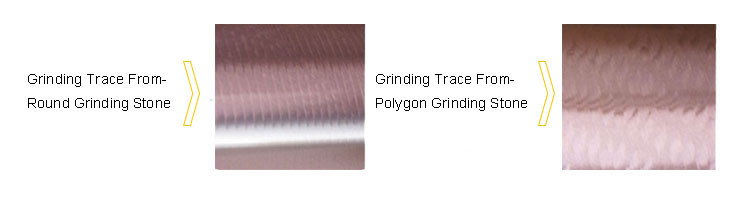

Diffrent Grinding Trace From Round And Polygon Shape Stone:

1.The polygon shape stone could eliminate the grinding traces normally caused by round stone;

2. It could avoid the traces being transcribed to printing materials directly.

3. It is particularly obvious for net gravure and colour-gradually-changing gravure .

Packaging & Shipping

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging serviceswill be provided, We also provide custom packaging services.

Thickness 50mm: 10pcs per carton

Thickness 70mm: 8pcs per carton

Thickness 100 mm: 6pcs per carton

Product detail pictures:

Related Product Guide:

Being supported by an innovative and experienced IT team, we could present technical support on pre-sales & after-sales service for High Quality for Precision Grinding Machine - Gravure Grinding Wheel Polishing Wheel – DongYun , The product will supply to all over the world, such as: Oslo, Provence, Barcelona, We integrate design, manufacture and export together with more than 100 skillful workers, strict quality controlling system and experienced technology.We keep long term business relationships with wholesaler and distributors form more than 50 countries, such as USA, UK, Canada, Europe and Africa etc.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.